cam and tappet experiment

The jerk for this cam is therefore in the form of a sine wave the same as the velocity. By contrast a solid lifter cam will leave the valve firmly on its seat before slapping the tappet rudely.

Pdf Analytic Analysis Of A Cam Mechanism

Cam and Tappet by Af idiahaisyah Salleh Submission date.

. CAM AND TAPPET EXPERIMENT Objectives The objectives of this experiment are. The results showed that for the particular geometry tested tappetbore friction torque accounted for about 13 of the total camtappetbore friction torque at 250 cam rpm. View Cam Tappetdocx from MEMB 331 at Tenaga National University Kajang.

1 Front View of Apparatus The following. Department of Energy Office of Scientific and Technical Information. Sophisticated instrumentation has been used to measure the.

Loosen the fixing screw 23 with the provided Allan key and insert the flat tappet followeApply a thin film of grease to the flat tappet. The objective of the experiment is to. In the present study the frictional force between the cam and tappet is directly measured using a load sensor installed in a test rig and the following is carried out.

The apparatus used is the cam and tappet apparatus with roller domed and flat followers equipped with dial indicator. - Investigate tappet. 1 For the first part of the experiment the flat follower.

Cam and tappet experiment By Coa_594Yurem 26 Jul 2022 Post a Comment Cone Under Picking Mechanism Flow Chart Chart Cone Chapter 6 Cams Schematic Of A Cam Tappet. Situated on the rear of the cam. Experimental evaluation of tappetbore and camtappet friction for a direct acting bucket tappet valvetrain.

Ad the acting class. The experiment is conducted with different types of cam which is simple harmonic cam and constant acceleration cam respectively. ENGINE CAM AND TAPPET WEAR 53 Fig.

Day and Date experiment performed. 13 Tappet 23- fixing screw 14-Interchangeable pick-up flat or cylindrical 16-Belt drive for the recording drum 24- knurled nut fixing the cam Fig. The relative sliding of tappet roller to cam has been experimentally determined by means of a simulator rig.

The jerk for this cam is therefore zero. The company recommends running a flat tappet or roller cam with. View Experiment 3 _ Cam and Tappetpdf from MECHANICAL MEMB331 at Tenaga National University Kajang.

There are five types of cams used that is convex tangent. COLLEGE OF ENGINEERING DEPARTMENT OF MECHANICAL ENGINEERING MEMB331 MACHINE DESIGN. Made available by US.

Firstly the changes of friction. 11 - Hardenable iron tappet face high limit structure 116 in off center - R 60 - nital etch on cast cams while alloyed chilled iron ap-pears to be. To compare the throw profile of two types of cams simple harmonic parabolic cam.

Statement of Purpose Objective. The plot for the harmonic cam is in the form of a cosine wave.

An Enhanced Flexible Dynamic Model And Experimental Verification For A Valve Train With Clearance And Multi Directional Deformations Sciencedirect

An Enhanced Flexible Dynamic Model And Experimental Verification For A Valve Train With Clearance And Multi Directional Deformations Sciencedirect

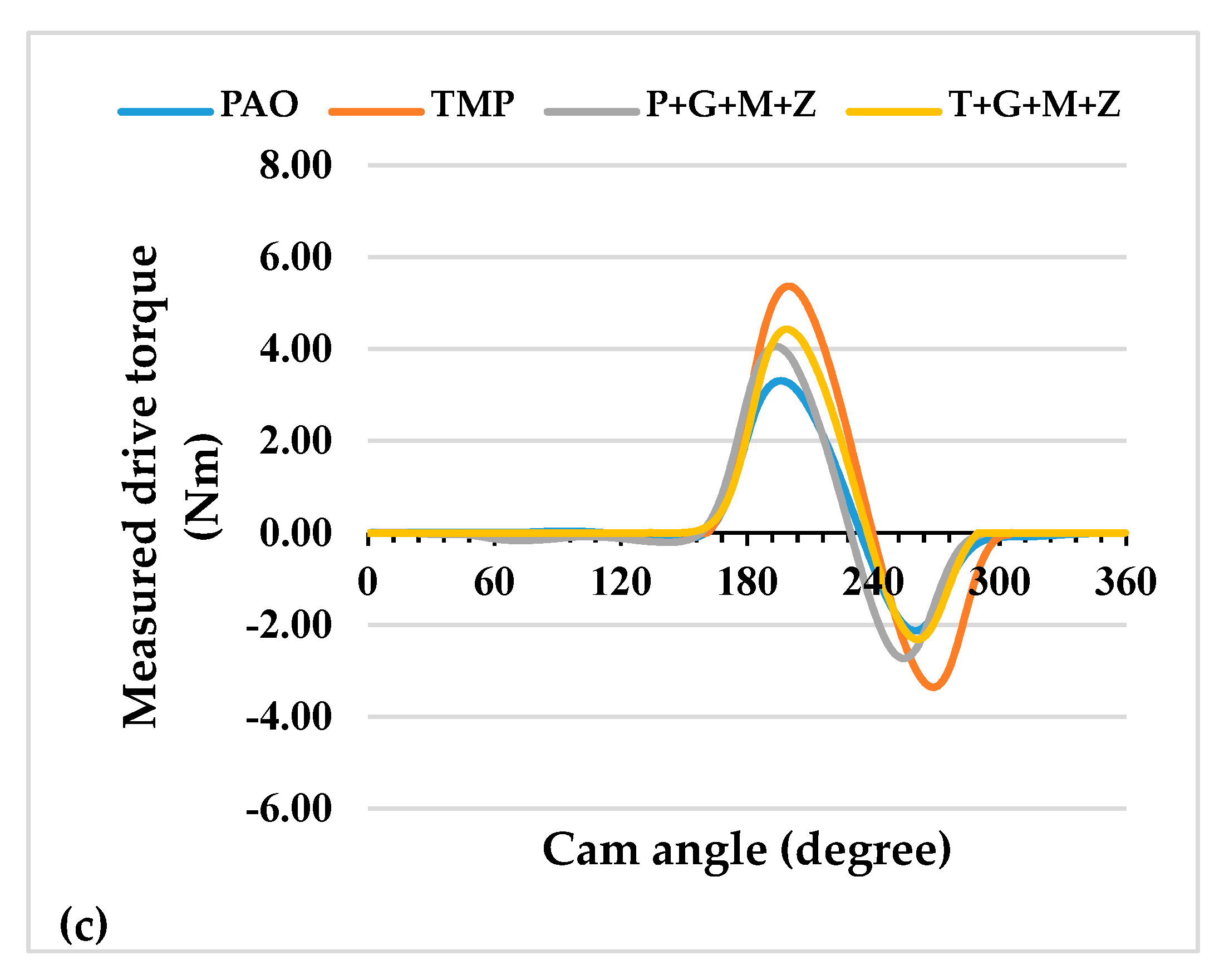

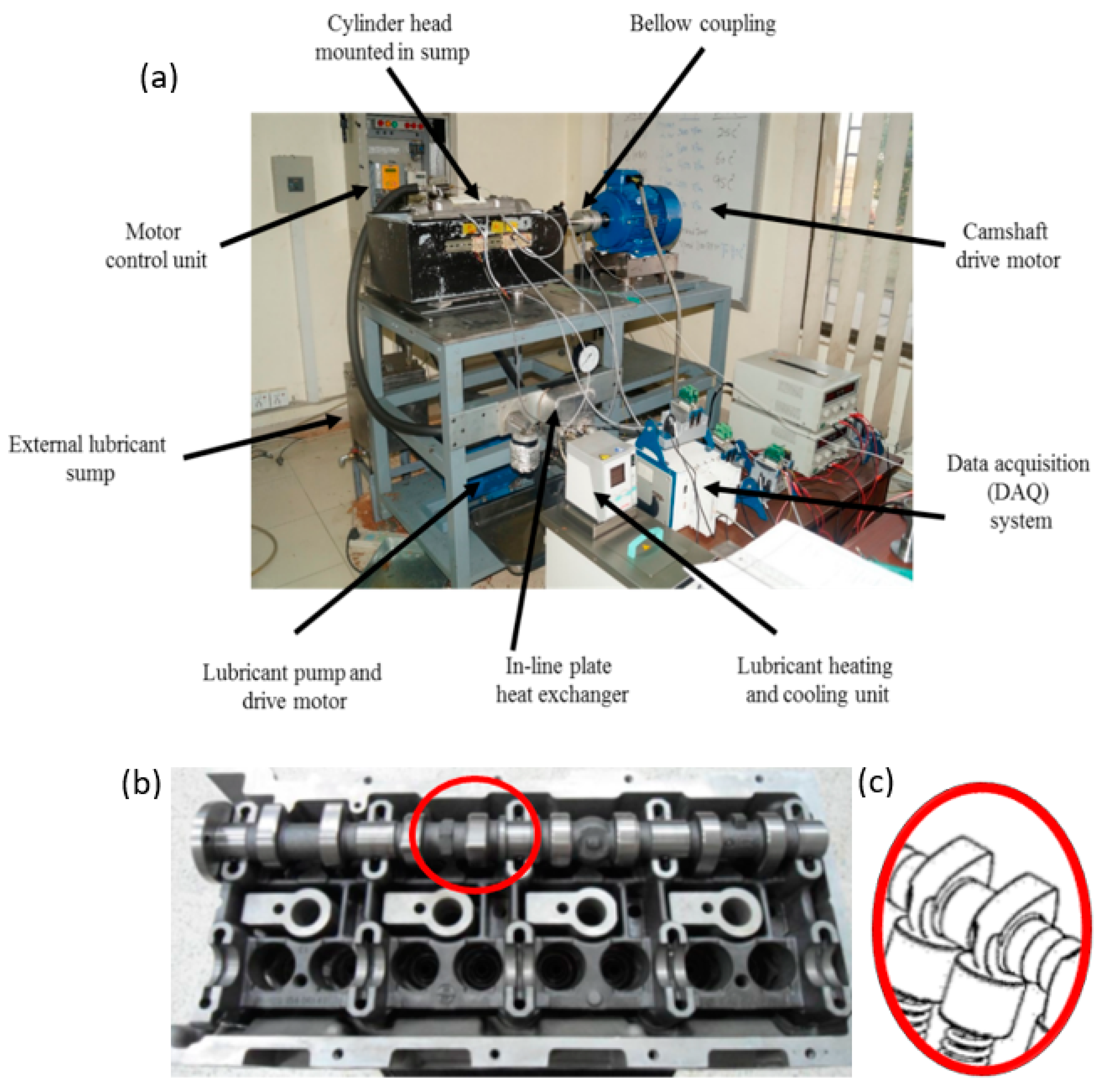

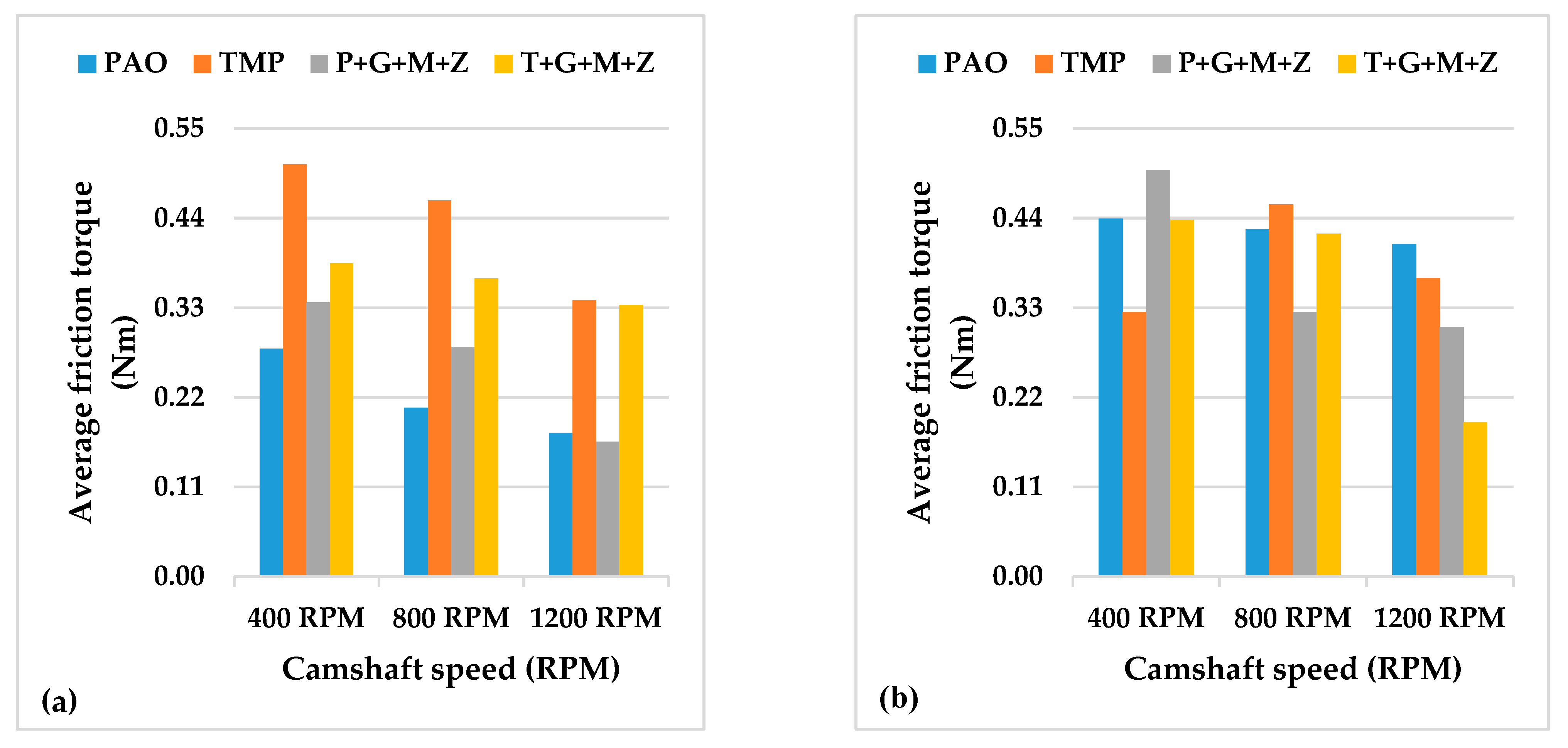

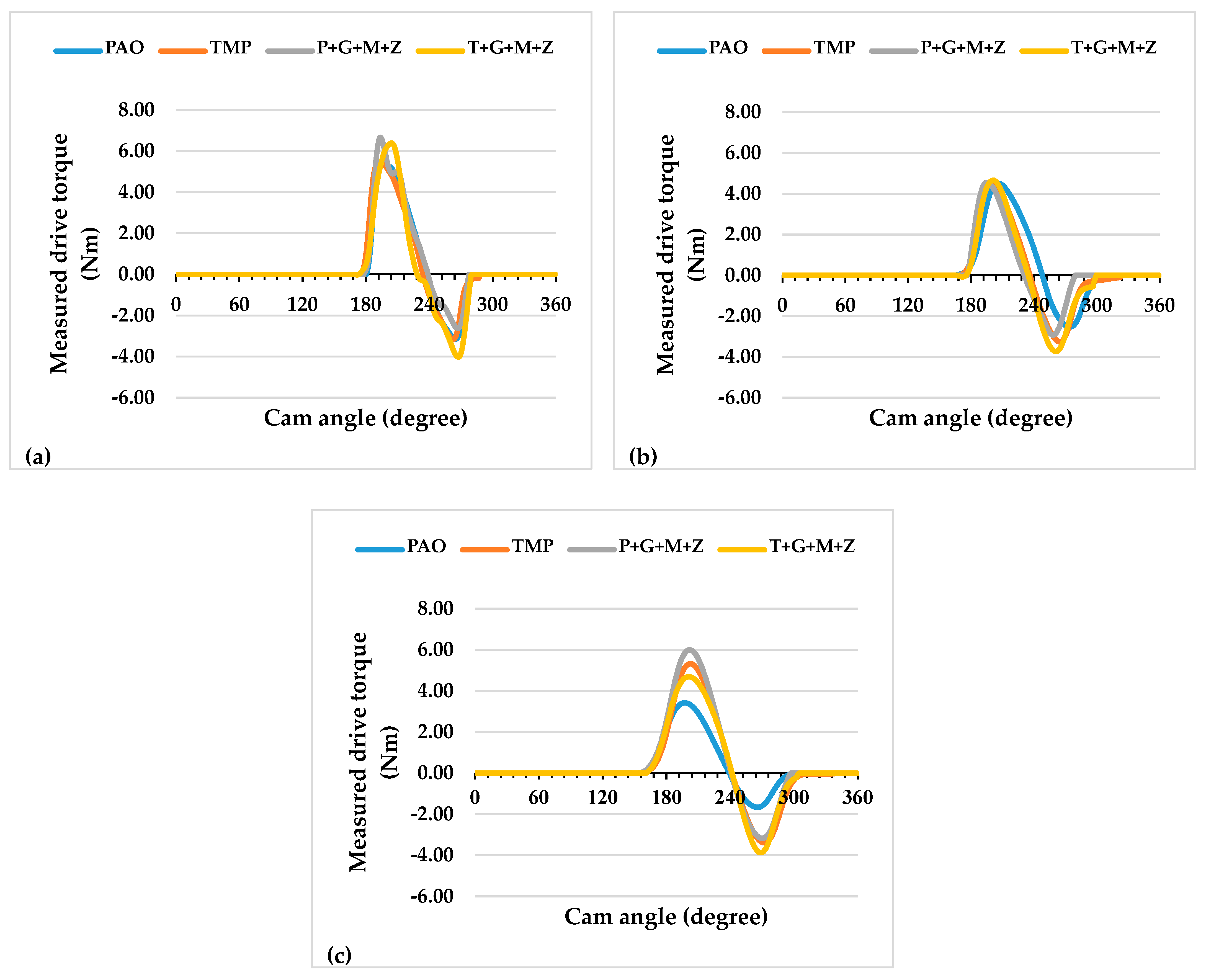

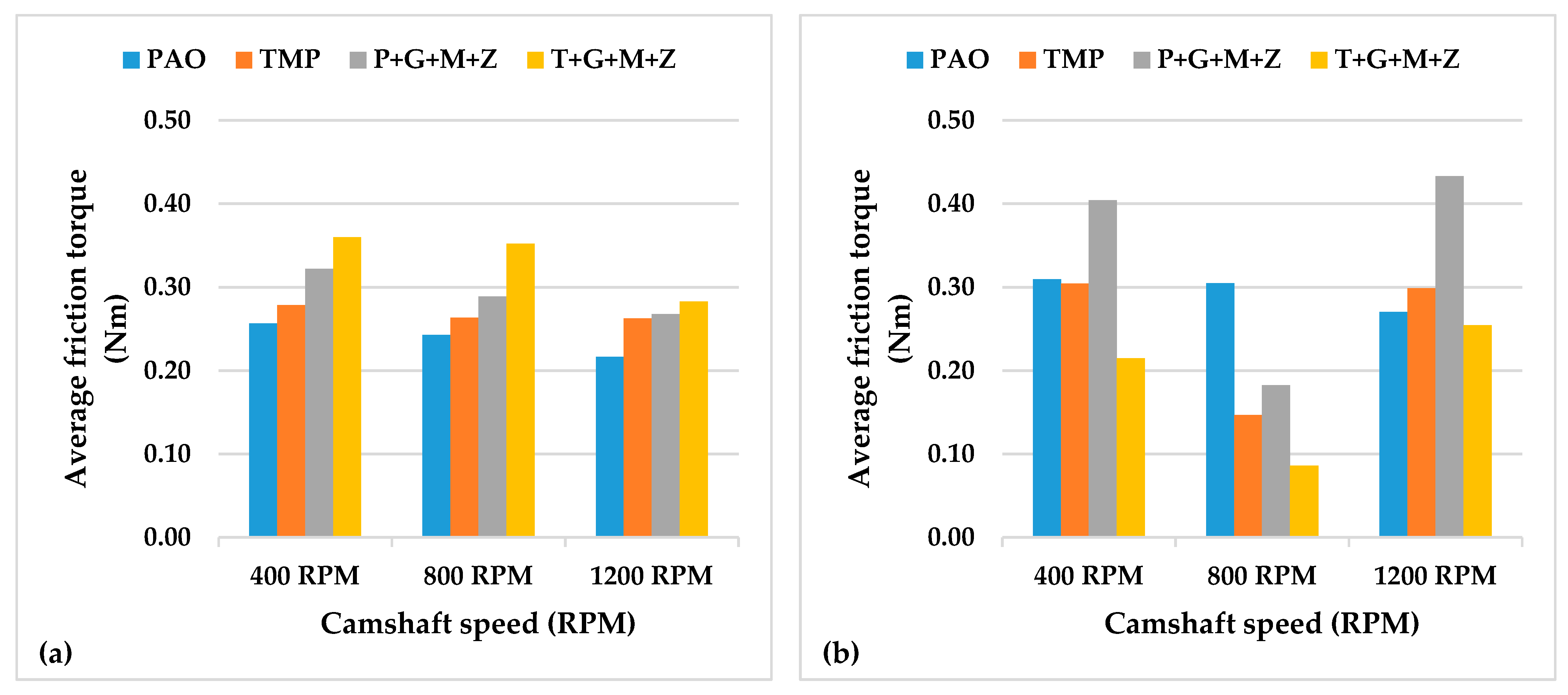

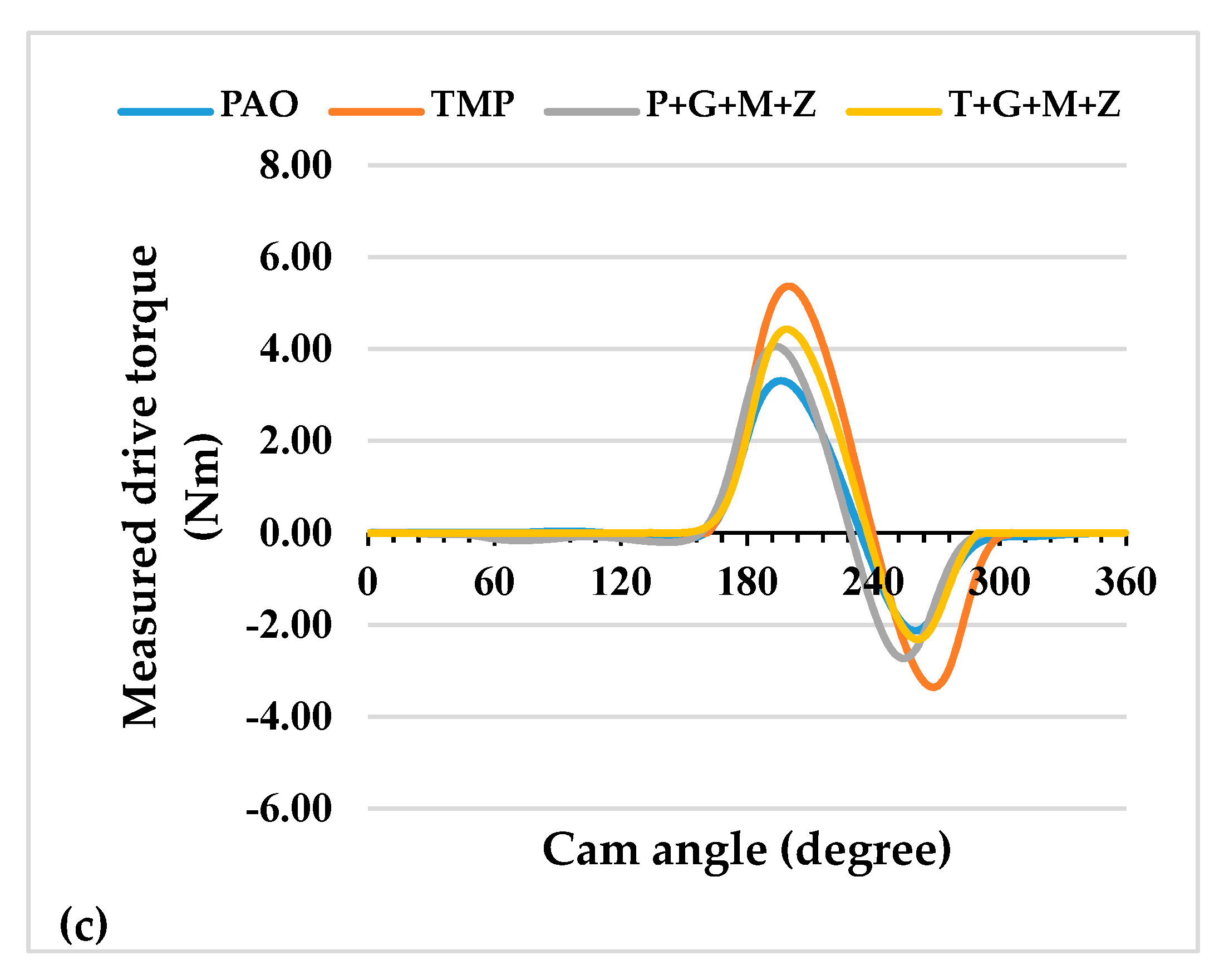

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

An Enhanced Flexible Dynamic Model And Experimental Verification For A Valve Train With Clearance And Multi Directional Deformations Sciencedirect

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

An Enhanced Flexible Dynamic Model And Experimental Verification For A Valve Train With Clearance And Multi Directional Deformations Sciencedirect

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

The Toughness Evaluation Of Crbn Coatings Doped With Ni Or Cu By Experiment And Fem Sciencedirect

Materials Free Full Text Friction And Wear Performance Evaluation Of Bio Lubricants And Dlc Coatings On Cam Tappet Interface Of Internal Combustion Engines Html

An Enhanced Flexible Dynamic Model And Experimental Verification For A Valve Train With Clearance And Multi Directional Deformations Sciencedirect